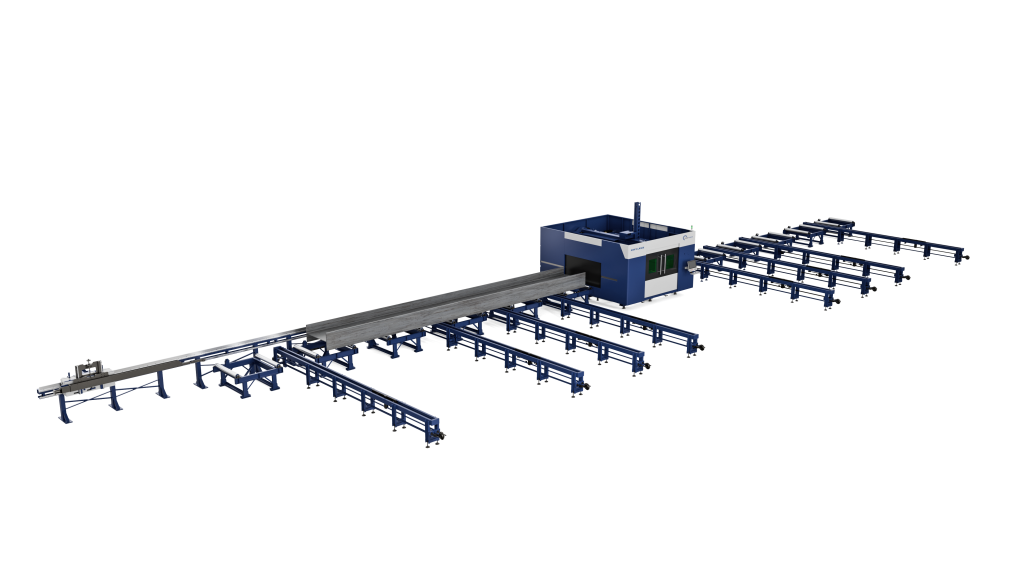

Fully Automatic Loading & Unloading, ensuring continuity and minimizing operator dependence.

● Support automatic loading and unloading of multiple H-beams;

● Implement zero tailings cutting with any port and graphic.

The feeding clamp quickly approaches the section steel, and after detecting the workpiece through the detection switch on the clamp, clamps and limits the H-beam to ensure accuracy and stability during cutting.

Fully Enclosed Cutting Environment

Equipped with thickened sheet metal protective cover, laser protection level is high to ensure production safety;

● Profile widths up to 1250mm;

● Profile heights up to 600mm;

● Supports up to 12 meters of entire H-steel for loading, cutting, and unloading.

Subvert Traditional Cutting Technology

● Copes are smooth and do not require additional grinding or shaping.

● Cutting off, bevel cut, locking edge cut, cut small holes can be done in one machine.

|

|

|

|

| ✔️ Model | ✔️ H12560LBF |

|---|---|

| H Beams Laser Cutter Series |

|

| Cutting range (H Beam) | 1250mm×600mm |

| Cutting range (Sheet Metal) | 26000mm×2500mm |

| Loading length | 12000mm |

| Bevel cut angle | 0-45° |

| X, Y axis positioning accuracy | ±0.08mm |

| Repeat positioning accuracy | ±0.08mm |

| A , B axis positioning accuracy | ±0.1° |

| Max. X, Y axis positioning speed | 40m/min |

| 3015HF | 4020HF | 6025HF | 8025HF | 10025HF | 12025HF | 12030HF | UNITS | |

|---|---|---|---|---|---|---|---|---|

| Machine Length | 9615 | 11230 | 15700 | 19200 | 24100 | 28400 | 28400 | mm |

| Machine Width | 3040 | 3470 | 4060 | 4060 | 4230 | 4230 | 4800 | mm |

| Machine Height | 2330 | 2320 | 2400 | 2400 | 2610 | 2610 | 2610 | mm |

| Nominal Sheet Size (X) | 3000 | 4000 | 6000 | 8000 | 10000 | 12000 | 12000 | mm |

| Nominal Sheet Size (Y) | 1500 | 2000 | 2500 | 2500 | 2500 | 2500 | 3000 | mm |

| X Axis Stroke | 3050 | 4030 | 6030 | 8100 | 10100 | 12100 | 12100 | mm |

| Y Axis Stroke | 1530 | 2020 | 2520 | 2520 | 2600 | 2600 | 3080 | mm |

| Z Axis Stroke | 120 | 120 | 400 | 400 | 400 | 400 | 400 | mm |

| X/Y Positioning Accuracy | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.05 | ±0.05 | ±0.05 | mm/m |

| X/Y Repositioning Accuracy | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.05 | ±0.05 | ±0.05 | mm |

| Max. Travelling Speed | 200 | 200 | 160 | 160 | 160 | 160 | 160 | m/min |

| Max. Accelerating Speed | 2.8 | 2.8 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | G |

| Max. Workbench Weight | 1800 | 3200 | 14400 | 19200 | 24000 | 28800 | 34400 | kg |

| Machine Weight (Approx.) | 10000 | 14000 | 20000 | 24000 | 29000 | 32000 | 34000 | kg |

The right to make changes to dimensions, construction, and equipment is reserved. ISO-9001-certified. The technical data can vary based on the chosen configuration of the machine.

| Cutting Head | Hans / Precitec/MAX Photonics |

| Focus Mode | Automatic |

| Cooling Mode | Water Cooled |

| Piercing Mode | 5 Stage |

| Laser Source | IPG (USA / Germany)/ MAX Photonics/ Han’s Laser Photonics (China) / Coreactive (Canada) |

| Rack | Gudel (Switzerland) |

| Pinion | Rexroth (Germany)/Hiwin(Taiwan) |

| Speed Reducers | Alpha (Germany)/Gudel (Switzerland)/Stober(Germany) |

| Servo Drives & Motors | Rexroth (Germany) |

| Computer | Industrial X64-based PC |

| Operating System | Windows 10 64 bit |

| CNC Software | Han’s 901 (Bosch Rexroth) |

| Display Size | 21” |

| Electrical System | Airtac/Parker |

| Gas Circuit Control – Oxygen, Nitrogen and Air | Lanny (Germany) |

| Laser and Cutting Head Cooling Device | Dual Circuit Industrial Chiller |

| Laser Source Enclosure | Han’s Laser |

The technical data can vary based on the chosen configuration of the machine.

|

|

|