Experience the pinnacle of precision and performance with our top-of-the-range fiber laser cutting machine.

Engineered for maximum efficiency, power, and accuracy, this premium model delivers unmatched speed,

edge quality, and reliability—designed for those who demand nothing but the best in industrial sheet metal cutting.

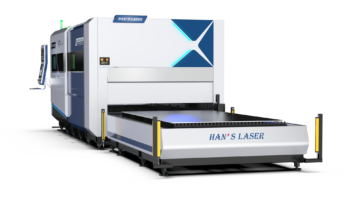

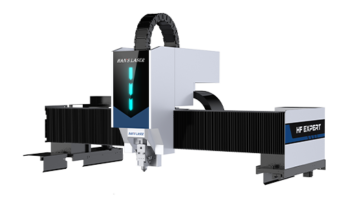

HF Series

High-productivity Laser Cutting Machine 3015 ⁄ 4020 ⁄ 6025 ⁄ 8025

Available power: 6kW ⁄ 12kW ⁄ 20kW ⁄ 30kW ⁄ 40kW ⁄ 50kW ⁄ 60kW

Overview

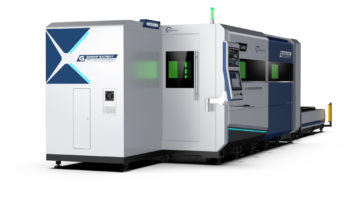

High-productivity Laser Cutting Machine with Optimal Economic Benefits

More reliability & stability, professional manufacturing process equipped with high-precision core transmission

components,long-term life time of components, good dimensional accuracy of parts. More Accessible & More

Flexible, thanks to adjustable operating terminal & front door + long side sliding door design,Loading/unloading for

variety of small piece turn to be easy, shorter response times for Demo-cut.

High-performance laser cutting with maximum cost efficiency!

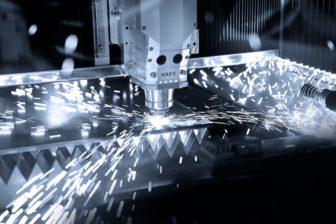

The HF Series high speed fiber laser cutting machine is Han’s premier 2D laser cutting machine.

Focusing on 12kW+ laser cutting and stable thick plate cutting, it can handle up to 40kW ultra-high power cutting.

It has a complete cutting database expertly produced over decades of R&D and includes zero 4 Han’s HF Series Han’s HF Series 5 second perforation, fast and stable thick plate piercing, low pressure cutting, mirror edge finishing and other advanced technologies, not available to common laser companies which are purely assembly focused.

HIGH ACCELERATION

The Laser Cutting machine can reach true 2.8G acceleration and 200m/min speeds over an entire nested sheet without sacrificing accuracy and machine durability.

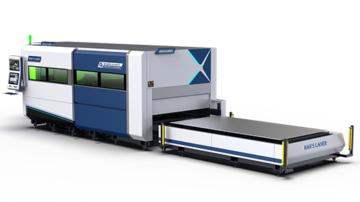

ULTRA-DURABLE FRAME

The hollow integrated frame is annealed and properly protected for high power usage; allowing up to 60kW without deformation.

EXTENSIVE CUTTING PARAMETERS

Every machine up to 60kW comes with Han’s expertly crafted precision cutting database; which realises the highest speed with best possible edge finish.

HAN’S 901 CNC SYSTEM

This system includes the world´s leading CNC developed by Han’s with Bosch-Rexroth while using Bosch-Rexroth servos to ensure the highest transmission performance possible. Combine this with almost 20 years at the forefront of laser cutting technology; Han’s have created the most efficient and professional solution for laser processing.

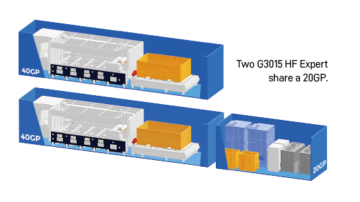

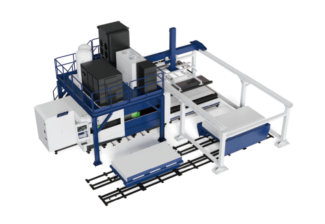

Strong technical support and many project experience, offer various automation solutions according to customer requirement.

HIGH – DYNAMIC & HIGH- PRODUCTIVITY

Thanks to optimized frame & extruded aluminum gantry design equipped with “Han’s 901 (Rexroth)” Real-time controller and powerful rexroth motors makes HF Expert reaches a very high speed and high acceleration, which means more parts or output in the same amount of time!

|

|

|

|

|

|

|

| ✔️ Model | ✔️ G3015 HF EXPRT | ✔️ G4020 HF EXPRT | ✔️ G6025 HF EXPERT | ✔️ G8025 HF EXPERT |

| HF Expert Series |  |

|

|

|

| Working Area | 3100mmx1600mm | 4100mmx2100mm | 6200mmx2600mm | 8200mmx2600mm |

| Max. Axis positioning speed (X/Y) | 280m/min | 280m/min | 160m/min | 160m/min |

| Max. Acceleration | 3g | 3g | 2.5g | 2.5g |

| Precision | 0.03mm | 0.03mm | 0.03mm | 0.03mm |

| Repetitiveness | 0.02mm | 0.02mm | 0.02mm | 0.02mm |

| Max. sheet weight | 2150kg/table | 3840kg/table | 7200kg/table | 9600kg/table |