Overview

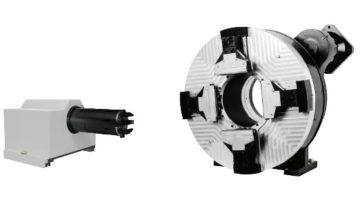

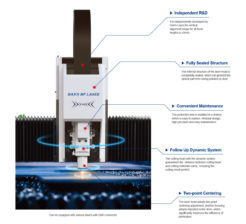

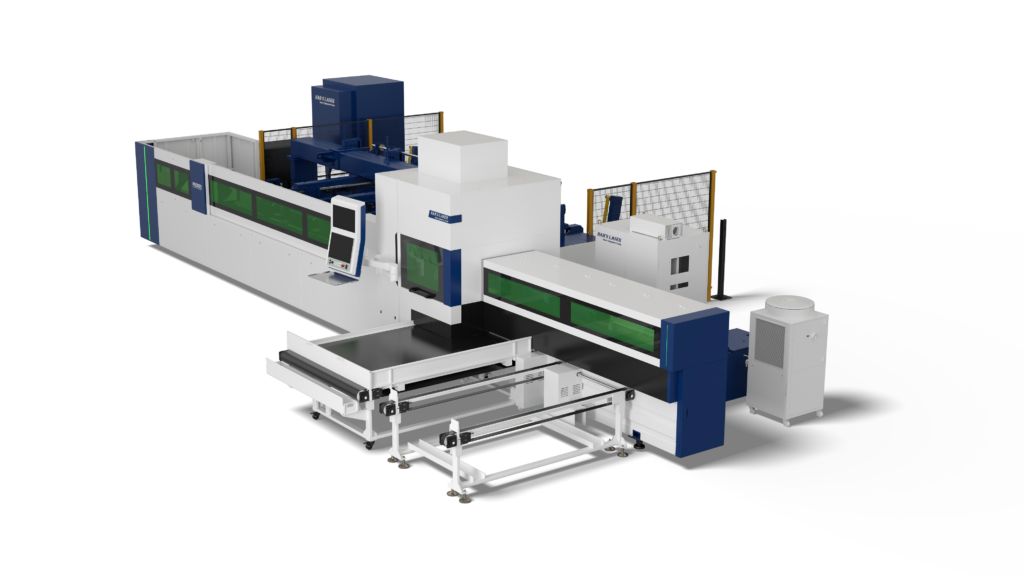

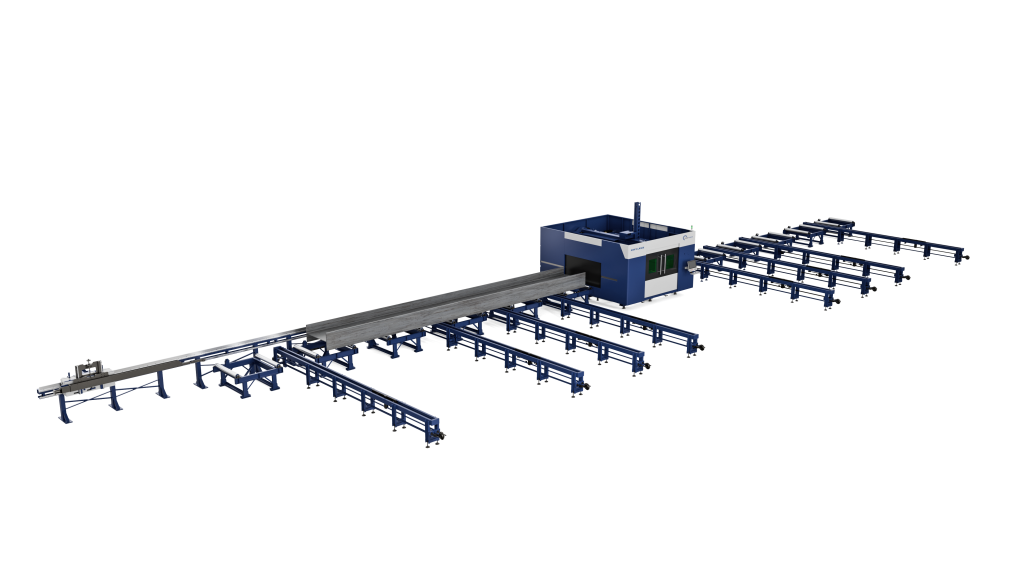

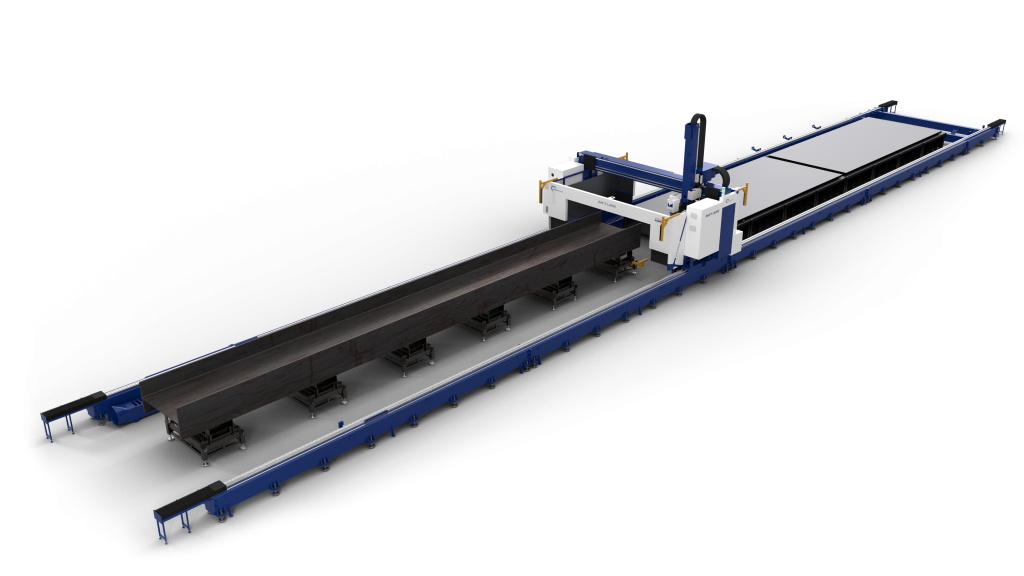

MPS-T5 Optical fiber laser pipe cutting machine

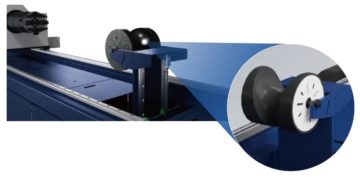

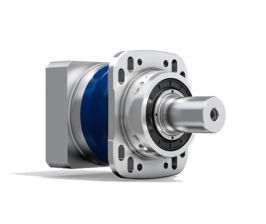

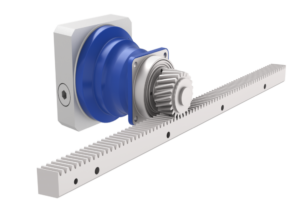

MPS-T5 is mainly faced with the laser cutting customer. The model adopts the gear and rack drive structure, pneumatic clamping chuck, and rotating propulsion, which can be used to cut the common square tube, round tube and rectangular tube.